Product Description:

Product Introduction: Industrial Flowserve Logix 3200MD Digital HART Positioner

The Industrial Flowserve Logix 3200MD Digital HART Positioner is an innovative solution that has been developed to enhance performance and optimize valve control in industrial automation systems. This state-of-the-art positioner utilizes cutting-edge piezo technology, which offers unparalleled reliability, precision, and responsiveness, even in the most demanding applications.

The Logix 3200MD provides superior control and monitoring of valve actuators, delivering consistent and accurate positioning that enhances process efficiency. Its digital communication protocol—HART (Highway Addressable Remote Transducer)—enables seamless integration with other devices and systems, offering flexibility and adaptability in various industrial settings.

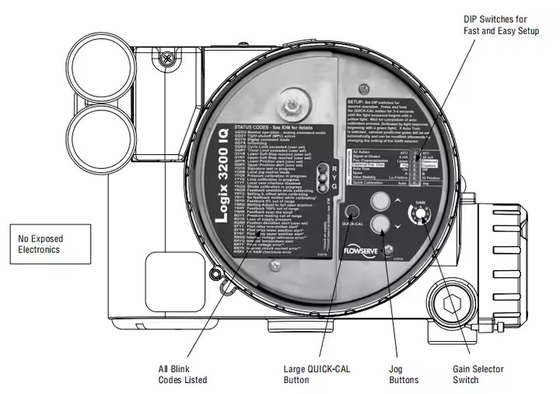

One of the standout features of the Logix 3200MD is its user-friendly configuration process. Whether you prefer using the local buttons directly on the device, a HART handheld communicator, or Flowserve's SoftTools software, setup and adjustments are simple and intuitive. This versatility ensures that the positioner can be easily tailored to meet specific system requirements without the need for complex programming.

Built to withstand the rigors of industrial environments, the Logix 3200MD combines durable construction with innovative technology to deliver outstanding performance. Whether optimizing flow control in a chemical plant, oil refinery, or other heavy-duty applications, the Flowserve Logix 3200MD positioner provides the accuracy and reliability needed to maintain smooth operations.

Features:

Key Features:

The product comes with the following key features:

Advanced Piezo Technology:

With advanced piezo technology, the product ensures precise and reliable valve positioning for improved process control. This feature guarantees that the valve will move to the specified position as commanded.

HART Communication:

HART communication enables seamless integration with existing systems for enhanced flexibility. The product can be easily integrated with other machines or systems to ensure greater efficiency.

User-Friendly Configuration:

The product can be configured via local buttons, HART handheld, or SoftTools software for easy setup and adjustments. This feature makes it easy for users to make changes to the settings to suit their requirements.

Durable and Reliable:

The product is built to handle harsh industrial environments with exceptional performance. Its high durability and reliability make it ideal for use in tough conditions.

Technical Parameters:

| Model Number |

Logix 3200MD |

| Condition |

New And Origin |

| Input |

4-20 MA |

| Industries |

Power,Chemicals,Water,Oil & Gas,General Industries,Mining |

| Diameter Nominal |

2.5 |

| Hysteresis |

0.2% |

| Customized support |

OEM |

| Connection |

Flange,Clamp,Thread, Sanity Thread |

| Brand Name |

Flowserve |

| Ambient Temperature |

-20°C To +60°C |

Valve Position Regulator, Pneumatic Valve Positioner, Smart Valve Positioner

Applications:

Flowserve provides a wide range of advanced solutions catering to various industries. Our top-notch products offer cutting-edge technology, exceptional reliability, and superior performance. Our systems are designed to optimize operations, enhance productivity, and improve efficiency across several sectors.

Below are some of the industries where Flowserve products make a significant impact.

Power Industry:

- Conventional Steam: Flowserve’s precision valve and control systems ensure the efficient operation of steam power plants, maintaining optimal performance in power generation.

- Combined Cycle: With advanced flow control solutions, Flowserve enhances the performance of combined cycle power plants by ensuring smooth integration between gas and steam turbines.

- Concentrated Solar Power (CSP): Flowserve’s innovative solutions help optimize energy capture and conversion processes in solar power plants, contributing to a more sustainable energy future.

- Biomass & MSW (Municipal Solid Waste): Flowserve’s products support the conversion of organic waste into energy, enabling efficient and environmentally friendly biomass energy production.

- Geothermal: Our systems are designed to handle high-pressure and high-temperature environments, ensuring reliable operation in geothermal power plants.

Chemicals Industry:

- Basic Chemicals (Organic & Inorganic): Flowserve offers reliable pumps, valves, and sealing systems to improve process flow and reduce downtime in the production of basic chemicals.

- Specialty Chemicals (Fine & Consumer): From fine chemicals to consumer products, Flowserve provides precision-engineered solutions that optimize the manufacturing process and ensure quality control.

- Biofuels: Flowserve supports the biofuels sector with advanced systems that enhance the production, storage, and distribution of renewable fuels.

- Pharmaceuticals: With a focus on safety, accuracy, and reliability, Flowserve’s solutions are integral to pharmaceutical manufacturing processes, ensuring strict compliance with industry standards.

- Petrochemicals: Flowserve’s products help streamline operations and improve efficiency in the production of petrochemical derivatives, enhancing process stability and output.

Water Industry:

- Water Management: Flowserve’s innovative water treatment systems help optimize the management of water resources, ensuring safe, sustainable water distribution and wastewater treatment.

Oil & Gas Industry:

- Upstream Exploration & Production: Flowserve solutions provide reliable and efficient flow control systems for exploration and production, ensuring optimal performance in harsh environments.

- Midstream Transportation: Our pumps, valves, and control systems support the transportation of oil and gas, ensuring safe and efficient pipeline operations.

- Downstream Processing: Flowserve technologies are widely used in refining and processing operations, ensuring the efficient transformation of crude oil into refined products.

General Industries:

- Pulp & Paper: Flowserve’s solutions enable the efficient processing of raw materials into paper products, improving productivity and reducing waste.

- Steel & Primary Metals: With robust flow control solutions, Flowserve supports the production of steel and metals, optimizing operations in demanding manufacturing environments.

- Food & Beverage: Flowserve’s sanitary pumps, valves, and seals ensure quality and safety in food and beverage manufacturing, meeting strict regulatory requirements.

- Mining: Our solutions enhance the extraction, transportation, and processing of minerals, contributing to more efficient and sustainable mining operations.

Flowserve is committed to delivering high-performance, reliable, and cost-effective solutions that drive innovation and improve operational efficiency in each of these industries. From power generation to mining, and from pharmaceuticals to water management, Flowserve products are at the heart of industry success, providing the technology and support needed for optimal results across the globe.

Support and Services:

The Control Valve Positioner product technical support and services include:

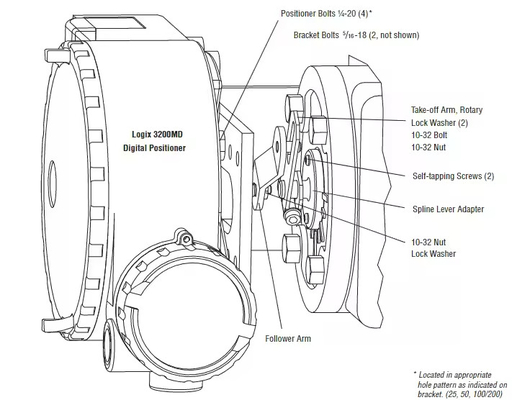

- Installation and set up guidance

- Troubleshooting assistance

- Maintenance and repair services

- Technical documentation and manuals

- Training and education programs

- Software and firmware updates

- Calibration and testing services

- Customization and engineering services

Packing and Shipping:

Product Packaging:

The Control Valve Positioner will be packaged securely in a sturdy box with foam inserts to ensure safe transport. Each unit will be individually wrapped in bubble wrap to prevent any scratches or damage during shipping.

Shipping:

All orders will be shipped within 24 hours of payment confirmation. We offer free standard shipping within the continental United States. Expedited shipping options are also available at an additional cost.

International shipping is available for an additional fee and delivery times may vary depending on the destination country.

Product Description:

Product Introduction: Industrial Flowserve Logix 3200MD Digital HART Positioner

The Industrial Flowserve Logix 3200MD Digital HART Positioner is an innovative solution that has been developed to enhance performance and optimize valve control in industrial automation systems. This state-of-the-art positioner utilizes cutting-edge piezo technology, which offers unparalleled reliability, precision, and responsiveness, even in the most demanding applications.

The Logix 3200MD provides superior control and monitoring of valve actuators, delivering consistent and accurate positioning that enhances process efficiency. Its digital communication protocol—HART (Highway Addressable Remote Transducer)—enables seamless integration with other devices and systems, offering flexibility and adaptability in various industrial settings.

One of the standout features of the Logix 3200MD is its user-friendly configuration process. Whether you prefer using the local buttons directly on the device, a HART handheld communicator, or Flowserve's SoftTools software, setup and adjustments are simple and intuitive. This versatility ensures that the positioner can be easily tailored to meet specific system requirements without the need for complex programming.

Built to withstand the rigors of industrial environments, the Logix 3200MD combines durable construction with innovative technology to deliver outstanding performance. Whether optimizing flow control in a chemical plant, oil refinery, or other heavy-duty applications, the Flowserve Logix 3200MD positioner provides the accuracy and reliability needed to maintain smooth operations.

Features:

Key Features:

The product comes with the following key features:

Advanced Piezo Technology:

With advanced piezo technology, the product ensures precise and reliable valve positioning for improved process control. This feature guarantees that the valve will move to the specified position as commanded.

HART Communication:

HART communication enables seamless integration with existing systems for enhanced flexibility. The product can be easily integrated with other machines or systems to ensure greater efficiency.

User-Friendly Configuration:

The product can be configured via local buttons, HART handheld, or SoftTools software for easy setup and adjustments. This feature makes it easy for users to make changes to the settings to suit their requirements.

Durable and Reliable:

The product is built to handle harsh industrial environments with exceptional performance. Its high durability and reliability make it ideal for use in tough conditions.

Technical Parameters:

| Model Number |

Logix 3200MD |

| Condition |

New And Origin |

| Input |

4-20 MA |

| Industries |

Power,Chemicals,Water,Oil & Gas,General Industries,Mining |

| Diameter Nominal |

2.5 |

| Hysteresis |

0.2% |

| Customized support |

OEM |

| Connection |

Flange,Clamp,Thread, Sanity Thread |

| Brand Name |

Flowserve |

| Ambient Temperature |

-20°C To +60°C |

Valve Position Regulator, Pneumatic Valve Positioner, Smart Valve Positioner

Applications:

Flowserve provides a wide range of advanced solutions catering to various industries. Our top-notch products offer cutting-edge technology, exceptional reliability, and superior performance. Our systems are designed to optimize operations, enhance productivity, and improve efficiency across several sectors.

Below are some of the industries where Flowserve products make a significant impact.

Power Industry:

- Conventional Steam: Flowserve’s precision valve and control systems ensure the efficient operation of steam power plants, maintaining optimal performance in power generation.

- Combined Cycle: With advanced flow control solutions, Flowserve enhances the performance of combined cycle power plants by ensuring smooth integration between gas and steam turbines.

- Concentrated Solar Power (CSP): Flowserve’s innovative solutions help optimize energy capture and conversion processes in solar power plants, contributing to a more sustainable energy future.

- Biomass & MSW (Municipal Solid Waste): Flowserve’s products support the conversion of organic waste into energy, enabling efficient and environmentally friendly biomass energy production.

- Geothermal: Our systems are designed to handle high-pressure and high-temperature environments, ensuring reliable operation in geothermal power plants.

Chemicals Industry:

- Basic Chemicals (Organic & Inorganic): Flowserve offers reliable pumps, valves, and sealing systems to improve process flow and reduce downtime in the production of basic chemicals.

- Specialty Chemicals (Fine & Consumer): From fine chemicals to consumer products, Flowserve provides precision-engineered solutions that optimize the manufacturing process and ensure quality control.

- Biofuels: Flowserve supports the biofuels sector with advanced systems that enhance the production, storage, and distribution of renewable fuels.

- Pharmaceuticals: With a focus on safety, accuracy, and reliability, Flowserve’s solutions are integral to pharmaceutical manufacturing processes, ensuring strict compliance with industry standards.

- Petrochemicals: Flowserve’s products help streamline operations and improve efficiency in the production of petrochemical derivatives, enhancing process stability and output.

Water Industry:

- Water Management: Flowserve’s innovative water treatment systems help optimize the management of water resources, ensuring safe, sustainable water distribution and wastewater treatment.

Oil & Gas Industry:

- Upstream Exploration & Production: Flowserve solutions provide reliable and efficient flow control systems for exploration and production, ensuring optimal performance in harsh environments.

- Midstream Transportation: Our pumps, valves, and control systems support the transportation of oil and gas, ensuring safe and efficient pipeline operations.

- Downstream Processing: Flowserve technologies are widely used in refining and processing operations, ensuring the efficient transformation of crude oil into refined products.

General Industries:

- Pulp & Paper: Flowserve’s solutions enable the efficient processing of raw materials into paper products, improving productivity and reducing waste.

- Steel & Primary Metals: With robust flow control solutions, Flowserve supports the production of steel and metals, optimizing operations in demanding manufacturing environments.

- Food & Beverage: Flowserve’s sanitary pumps, valves, and seals ensure quality and safety in food and beverage manufacturing, meeting strict regulatory requirements.

- Mining: Our solutions enhance the extraction, transportation, and processing of minerals, contributing to more efficient and sustainable mining operations.

Flowserve is committed to delivering high-performance, reliable, and cost-effective solutions that drive innovation and improve operational efficiency in each of these industries. From power generation to mining, and from pharmaceuticals to water management, Flowserve products are at the heart of industry success, providing the technology and support needed for optimal results across the globe.

Support and Services:

The Control Valve Positioner product technical support and services include:

- Installation and set up guidance

- Troubleshooting assistance

- Maintenance and repair services

- Technical documentation and manuals

- Training and education programs

- Software and firmware updates

- Calibration and testing services

- Customization and engineering services

Packing and Shipping:

Product Packaging:

The Control Valve Positioner will be packaged securely in a sturdy box with foam inserts to ensure safe transport. Each unit will be individually wrapped in bubble wrap to prevent any scratches or damage during shipping.

Shipping:

All orders will be shipped within 24 hours of payment confirmation. We offer free standard shipping within the continental United States. Expedited shipping options are also available at an additional cost.

International shipping is available for an additional fee and delivery times may vary depending on the destination country.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!