Product Description:

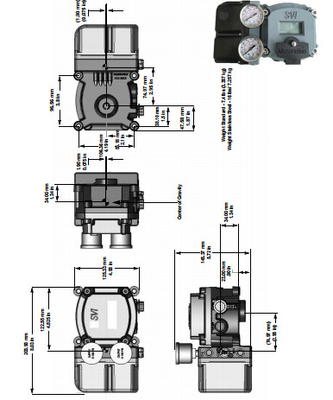

The SVI™ II AP (Smart Valve Interface, Advanced Performance) is an advanced and highly efficient digital valve positioner that comes equipped with a 32-bit microprocessor. This innovative instrument is designed to have a local interface that controls a pneumatic actuator through the use of a two-wire 4-20mA control signal. With bi-directional communication capabilities that utilize the HART® protocol, this cutting-edge positioner offers unmatched levels of control and flexibility.

What makes the SVI™ II AP so special is its universal design, which enables easy retrofitting in place of existing analog positioners. Whether you're working with Masoneilan or non-Masoneilan pneumatic actuators, be it single-acting or double-acting, you can trust the SVI™ II AP to deliver outstanding results. With this instrument, you can save time and money, while achieving optimal levels of performance from your pneumatic actuator.

So, if you're looking for a reliable digital valve positioner that can offer you greater control, flexibility, and efficiency, look no further than the SVI™ II AP. This industry-leading instrument is designed to deliver consistent and accurate results, while also offering ease of use and unparalleled ease of retrofit. It's the smart choice for professionals who demand the best.

Features:

Non-Contact Position Sensing Technology:

The Non-Contact Position Sensing Technology is an innovative approach that allows positioning sensing through the housing. Unlike traditional sensors, this technology does not require any mechanical moving parts entering the main housing cavity. As a result, the lifespan of the sensing mechanism is extended, and the need for constant maintenance is minimized, which ultimately results in cost savings and improved reliability.

One significant advantage of Non-Contact Position Sensing Technology is its simple mounting procedure. This technology is designed to be easily mounted, even in the most challenging conditions, with little or no technical knowledge required. This feature saves time and reduces the cost of installation significantly.

Easy, Simple, Accurate:

The Non-Contact Position Sensing Technology is incredibly easy and simple to use. It features an LCD and pushbuttons that are operable in all certified hazardous environments. This design makes it possible for users to operate and monitor the sensor, even in the most challenging industrial settings.

The technology has a quick and accurate commissioning method that features auto stops and auto-tune methods. This function enables the sensor to self-adjust and calibrate, ensuring fast and precise installation. Additionally, one design fits many applications, whether rotary or linear, remote or local. This remarkable versatility makes it suitable for a wide variety of applications, saving users both time and resources.

Technical Parameters:

| Product Attribute |

Value |

| Signal Communication |

HART 5 Or 7 Over 4-20mA |

| Diagnostics |

Standard Diagnostics, Advanced Diagnostics |

| Model Number |

SVI II |

| Supply Pressure |

20 To 150psi |

| Operating Temperature |

-50°C To +85°C |

| Type |

Digital Valve Positioner |

| Pneumatics Action |

Single Or Double Acting, Fail Safe, Rotary And Linear |

| Air Delivery |

280 SLPM @ 30psi |

| Features |

Easy, Simple, Accurate |

| Brand Name |

Masoneilan |

Applications:

Power Generation, Refining, Petrochemicals, Midstream Oil & Gas, Upstream Oil & Gas

In the energy industry, there are several different sectors that contribute to the production and distribution of various fuels. These sectors include power generation, refining, petrochemicals, midstream oil & gas, and upstream oil & gas.

Power generation involves the production of electricity through various means, such as steam turbine generators, gas turbines, and heat recovery steam generators. Other key applications include the use of a condenser and cooling tower, as well as building facilities for reactors, turbines, and balance of plant systems.

In refining and petrochemicals, the focus is on the processing of crude oil and other raw materials to produce a range of products. Key applications include distillation, hydroprocessing, reforming, cracking, secondary processes, blending, quenching & fractioning, and charge gas compression.

Midstream and upstream operations involve the transportation, processing, and extraction of oil and gas. Key applications include pipeline integrity and operations, dehydration, refrigeration, liquifaction, loading/shipping, regasification, and auxillary systems such as dehydration and compression.

Support and Services:

The Control Valve Positioner product offers a range of technical support and services to ensure optimal performance and efficiency:

- Installation and commissioning support

- Product training and education

- Maintenance and repair services

- Remote monitoring and diagnostics

- Engineering support for custom applications

- Upgrades and retrofits

Our team of experts is available to assist with any questions or issues related to the Control Valve Positioner product.

Packing and Shipping:

Product Packaging:

The Control Valve Positioner product will be carefully packaged in a sturdy cardboard box to ensure its safe delivery. The box will be labeled with the product name and any necessary handling instructions. Inside the box, the product will be securely wrapped in bubble wrap or foam padding to prevent any damage during transportation. The package will also include a user manual and any necessary accessories.

Shipping:

The Control Valve Positioner product will be shipped via a reliable courier service to ensure timely and safe delivery. Shipping options will be provided at checkout and customers can choose their preferred delivery method. Shipping fees will vary depending on the destination and shipping method selected. Customers will receive a tracking number once the product has been shipped so they can monitor the delivery status.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews