Product Description:

There are several advantages to this system. Firstly, it is highly versatile in terms of its mounting position. It can be used for both normal and split-range operations, making it a very adaptable solution for a variety of different applications.

Another key benefit of this system is its excellent dynamic response. This means that it can react very quickly to changes in the system, making it a very responsive and efficient solution.

In addition, this system has a negligibly small influence of supply air, which means that it is able to function effectively even in conditions where there are fluctuations in the air supply. This is further enhanced by the ability to adjust the proportional band (P band), which ensures that the system can be fine-tuned to deliver the exact output required for a given application.

Other features of this system include adjustable air output capacity, low air supply consumption, and high resilience to mechanical vibrations. These combine to create a system that is low-maintenance, compact, and very robust.

- Mounting position: any

- Suitable for: normal or split-range operation

- Dynamic response: excellent

- Influence of supply air: negligibly small

- Proportional band: adjustable

- Air output capacity: adjustable

- Air supply consumption: low

- Resilience to mechanical vibrations: high

- Design: low-maintenance and compact

Features:

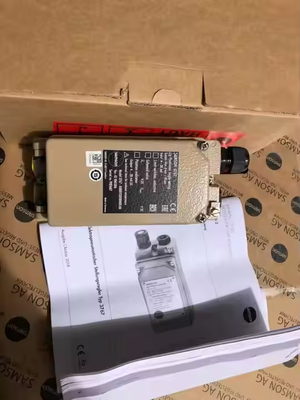

Electropneumatic Positioner

The Electropneumatic Positioner is a reliable and efficient device used for positioning linear and rotary actuators. It is built with a die-cast aluminum or stainless steel housing that guarantees durability. The attachment to linear actuators is according to IEC 60534-6 or SAMSON integral attachment; while the attachment to rotary actuators is according to VDI/VDE 3845. The device can also be attached to double-acting actuators with Type 3710 Reversing Amplifier.

The Electropneumatic Positioner is designed to be compact and low-maintenance. It can be mounted in any position and is insensitive to mechanical vibrations. It has a reversible direction of action and an excellent dynamic response. The device is capable of normal and split-range operation, and the proportional (P) band is adjustable. It also has adjustable air output capacity and low supply air consumption for efficient operation.

Features:

- Reliable and efficient positioning of linear and rotary actuators

- Die-cast aluminum or stainless steel housing for durability

- Attachment to linear actuators according to IEC 60534-6 or SAMSON integral attachment

- Attachment to rotary actuators according to VDI/VDE 3845

- Attachment to double-acting actuators with Type 3710 Reversing Amplifier

- Compact and low-maintenance design

- Movable in any position and insensitive to mechanical vibrations

- Reversible direction of action and excellent dynamic response

- Normal and split-range operation

- Adjustable proportional (P) band and air output capacity

- Low supply air consumption for efficient operation

Technical Parameters:

| Brand Name: |

Samson |

| Product: |

Electropneumatic Positioner |

| Usage: |

Challenging Transit Times And Ambient Conditions |

| Actuator: |

Linear Or Rotary |

| Material: |

Aluminum |

| Control Loop: |

4 To 20 MA |

| Communication: |

Without |

| Diagnostics: |

Without |

| Customized Support: |

OEM |

| Warranty: |

1 Year |

Applications:

Positioners are devices that are used to accurately control the position of a valve. They are necessary for optimizing valve performance and ensuring precise control of the flow rate. These devices can be attached to pneumatic control valves to enhance their functionality.

There are two types of positioners available: single-acting positioners and double-acting positioners. Single-acting positioners are designed to function with a single pneumatic input signal. These positioners are generally less expensive and consume less energy compared to their double-acting counterparts.

On the other hand, double-acting positioners use two pneumatic input signals to control the valve position. These positioners can provide greater accuracy and control compared to single-acting positioners. Double-acting positioners can also be used in applications where fail-safe valve positions are required.

In conclusion, both single-acting and double-acting positioners can be attached to pneumatic control valves to optimize valve performance and ensure precise control of the flow rate. The choice between the two types of positioners will depend on the specific application requirements, such as accuracy and fail-safe valve positions.

Support and Services:

Our Control Valve Positioner product comes with comprehensive technical support and services to ensure optimal performance and efficient operation. Our team of experienced engineers and technicians can provide assistance with installation, configuration, calibration, and troubleshooting. We also offer training programs to help our customers understand the features and functionality of our product. In addition, we provide regular maintenance and repair services to keep your Control Valve Positioner in top condition. Contact us for more information on our technical support and services.

Packing and Shipping:

Product Packaging:

- The control valve positioner will be packaged in a sturdy cardboard box.

- The box will be sealed with packaging tape to ensure it stays closed during shipping.

- Inside the box, the product will be surrounded by foam padding to protect it from damage during shipping.

Shipping:

- The control valve positioner will be shipped via a reputable courier service.

- Shipping times and costs will vary depending on the destination.

- Customers will receive a tracking number to monitor their shipment.

- If any damage occurs during shipping, customers should contact the seller immediately to arrange for a replacement.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews