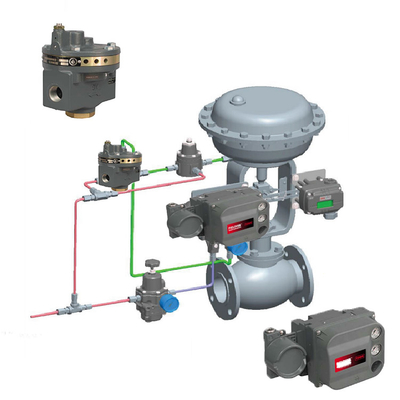

Product Description:

The Fisher FIELDVUE DVC6200 instrument offers a range of benefits to improve your operation. This device enables your system to operate much closer to the setpoint, providing greater accuracy in control. This increased precision helps maintain consistent quality in product output, which is a crucial factor in many industrial operations.

In addition to enhanced accuracy, the FIELDVUE DVC6200 also features Performance Diagnostics that allow for real-time monitoring of valve operation. By tracking performance and reliability metrics online, you can identify any issues that may be impacting your operation. This helps improve uptime, reduce maintenance costs and prevent any production disruptions due to valve failures.

Overall, the Fisher FIELDVUE DVC6200 is an essential tool for anyone seeking to maximize the efficiency and effectiveness of their industrial operation. With its advanced features and capabilities, this instrument offers a complete solution to help you achieve your production goals.

Features:

The DVC6200 is an advanced control valve positioner that is designed to deliver high performance with minimal maintenance requirements. It features a linkage-less feedback system that eliminates physical contact, which in turn reduces wear and tear on parts.

The fully encapsulated electronics of the DVC6200 are resistant to the effects of vibration, temperature, and corrosive atmospheres. This makes it an ideal solution for harsh industrial environments where reliability is critical.

In addition to its rugged design, the DVC6200 offers quick responsiveness to large step changes and precise control for small setpoint changes. This level of accuracy is achieved through digital communication and advanced control algorithms.

The DVC6200 is also a HART communicating device, which means that information can be accessed anywhere along the loop. This gives operators more flexibility and control over their valve systems, and it can also reduce exposure to hazardous environments.

Another advantage of the DVC6200 is its modular design. Critical working components can be replaced without the need to remove field wiring or pneumatic tubing. This makes maintenance faster and easier, which can result in significant hardware and installation cost savings over the lifetime of the valve.

Finally, the DVC6200 also features a self-diagnostic capability that provides valve performance and health evaluations. Digital communication allows for easy access to the condition of the valve, which can help operators make more informed decisions about maintenance and repairs.

The DVC6200 is an advanced control valve positioner that is designed to deliver high performance with minimal maintenance requirements. It features a linkage-less feedback system that eliminates physical contact, which in turn reduces wear and tear on parts.

The fully encapsulated electronics of the DVC6200 are resistant to the effects of vibration, temperature, and corrosive atmospheres. This makes it an ideal solution for harsh industrial environments where reliability is critical.

In addition to its rugged design, the DVC6200 offers quick responsiveness to large step changes and precise control for small setpoint changes . This level of accuracy is achieved through digital communication and advanced control algorithms.

The DVC6200 is also a HART communicating device , which means that information can be accessed anywhere along the loop. This gives operators more flexibility and control over their valve systems, and it can also reduce exposure to hazardous environments.

Another advantage of the DVC6200 is its modular design . Critical working components can be replaced without the need to remove field wiring or pneumatic tubing. This makes maintenance faster and easier, which can result in significant hardware and installation cost savings over the lifetime of the valve.

Finally, the DVC6200 also features a self-diagnostic capability that provides valve performance and health evaluations. Digital communication allows for easy access to the condition of the valve, which can help operators make more informed decisions about maintenance and repairs.

Technical Parameters:

| Area Classification | Explosion Proof, Intrinsically Safe, FISCO, Type N, Flame Proof, Non-incendive For FM |

| Communication Protocol | 4-20 MA HART |

| Power Source | Local |

| Model Number | DVC6200 |

| Diagnostics | Yes |

| Supply Media | Air, Natural Gas, Nitrogen |

| Mounting Type | Integral Mounted |

| Data Interface | Wired |

| Position Control | Throttling Control, On/Off |

| Brand Name | FISHER |

Applications:

The Fisher DVC6200 valve positioner is a reliable and precise device that is widely used in several industrial sectors. Its popularity is due to its ability to enhance system reliability and reduce maintenance costs. This device is considered as an intelligent valve positioner and is primarily used in various areas like:

- Process Control: In chemical, oil, and gas industries to maintain parameters such as flow, pressure, and temperature.

- Power Plants: Regulating valves in boilers and turbines for stable operation.

- Water Treatment: Managing inflow and outflow valves to ensure water quality.

- Food & Beverage: Controlling fluid valves to maintain consistent product quality.

- Pharmaceuticals: Providing precise control in clean environments.

The Fisher DVC6200 valve positioner is an excellent solution for various industrial sectors as it can maintain vital parameters to ensure the smooth operation of the system. Power plants can easily regulate valves using this device in boilers and turbines, while water treatment plants can manage the inflow and outflow valves to maintain the water quality. Additionally, the device is also beneficial in food & beverage and pharmaceutical sectors, where the precise control of fluid valves is necessary to maintain product quality.

Moreover, this device is equipped with digital communication and self-diagnostics technology, which enhances the system's reliability and reduces maintenance costs. Due to its advanced features and usefulness, the Fisher DVC6200 valve positioner has become a popular choice industry-wide.

Support and Services:

The Control Valve Positioner is a high-precision device designed to ensure accurate and stable control of valves in various industrial applications. Our product technical support and services include:

- On-site installation and commissioning

- Remote technical support and troubleshooting

- Regular maintenance and calibration services

- Spare parts and accessories supply

- Customized training programs for operators and maintenance personnel

Our team of experienced engineers and technicians are dedicated to providing you with the highest level of technical support and services to ensure optimal performance and reliability of your Control Valve Positioner.

Packing and Shipping:

Product Packaging:

- The control valve positioner will be securely packaged in a sturdy cardboard box to prevent any damage during shipping.

- The box will be labeled with the product name and any necessary handling instructions.

- Inside the box, the positioner will be wrapped in bubble wrap or other protective material to further prevent any damage.

Shipping:

- The control valve positioner will be shipped via a reputable courier service or shipping company.

- The shipping cost will be calculated based on the destination and shipping speed selected by the customer.

- The customer will receive a tracking number to monitor the progress of their shipment.

- The estimated delivery date will be provided to the customer at the time of purchase.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews