Product Description:

The use of the Fisher FIELDVUE DVC6200 instrument can bring significant benefits to your operation. This equipment helps to improve product quality through more precise control, allowing your operation to run closer to its setpoint. This level of accuracy helps to ensure that your products are produced consistently to meet your quality standards.

In addition to precise control, the FIELDVUE Performance Diagnostics feature provides online monitoring of valve operation. This advanced tool evaluates performance and reliability to identify potential issues before they become major problems. Such preventative maintenance can help to extend the life of your equipment and reduce the likelihood of downtime during critical operation.

Whether you are looking to improve production quality or reduce the risk of downtime in your operation, the Fisher FIELDVUE DVC6200 instrument offers a valuable solution. Its combination of precise control and advanced monitoring and diagnostics tools make it an essential investment in any operation where reliability and quality are crucial.

Features:

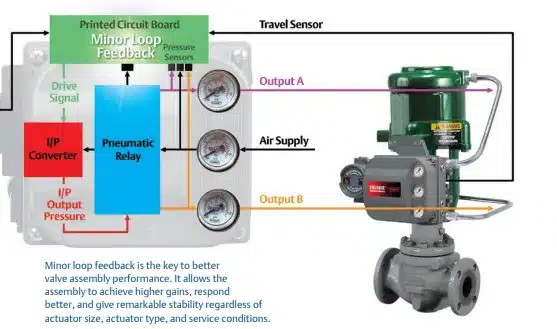

The linkage-less feedback system of the DVC6200 is designed for high performance. The system eliminates physical contact, thus preventing wearing on parts. This results in a longer working life for the valve and less maintenance costs.

The electronics of the DVC6200 are fully encapsulated, making them resistant to vibration, temperature changes, and corrosive atmospheres. This means the valve can be used in a wide variety of harsh environments without being affected by external factors.

The DVC6200 provides quick responsiveness to large step changes and offers precise control for small setpoint changes. This feature ensures that the valve can be used for a wide variety of applications with varying requirements for control.

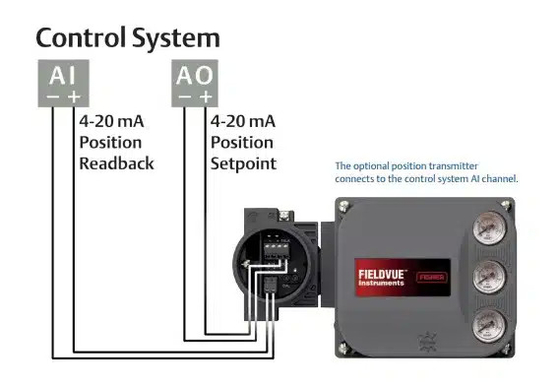

The valve is a HART communicating device, allowing information to be accessed anywhere along the loop. This feature makes it easier to evaluate valves in hard to reach locations and reduces exposure to hazardous environments, which can improve safety standards.

The modular design of the DVC6200 allows critical working components to be replaced without removing field wiring or pneumatic tubing. This feature offers a convenient way to perform maintenance on the valve and can save significant hardware and installation costs when integrated into a control system.

The self-diagnostic capability of the DVC6200 provides valve performance and health evaluation. This feature gives users easy access to the valve condition and allows for quick detection of any issues before they become critical.

Digital communication is another feature of the DVC6200 that allows easy access to the condition of the valve. This feature makes it easier for users to monitor and maintain the valve's performance, ultimately improving the efficiency of the valve.

Technical Parameters:

| Product Attribute |

Value |

| Process Control |

Flow, Pressure, Temperature, Level |

| Input Signal |

Electric |

| Model Number |

DVC6200 |

| Diagnostics |

Yes |

| Max Outlet Pressure |

145 Psig |

| Data Interface |

Wired |

| Brand Name |

FISHER |

| Operating Temperature |

Standard Temperature, High Temperature |

| Supply Media |

Air, Natural Gas, Nitrogen |

| Position Control |

Throttling Control, On/Off |

This product is a Pneumatic Valve Positioner which provides Valve Position Automation and Valve Position Regulator.

Applications:

The Fisher DVC6200 valve positioner is a highly reliable and precise device that is extensively used across various industrial sectors. This intelligent valve positioner serves numerous purposes in industries like chemical, oil and gas, power plants, water treatment, food and beverage, and pharmaceuticals.

In chemical, oil, and gas industries, the Fisher DVC6200 valve positioner primarily helps in maintaining parameters like flow, pressure, and temperature. It also assists in regulating valves in boilers and turbines for stable operation in power plants. In water treatment plants, it helps manage inflow and outflow valves to ensure the quality of treated water.

The device also plays an essential role in the food and beverage industry by controlling fluid valves for maintaining consistent product quality. It provides precise control in clean environments to pharmaceuticals, making it an ideal device for maintaining system reliability.

The Fisher DVC6200 valve positioner stands out from its counterparts as its digital communication and self-diagnostics enhance the reliability of industrial systems. Additionally, these features reduce maintenance costs, making it a highly cost-effective option for various sectors that require precision in valve position control.

Support and Services:

The Control Valve Positioner product technical support and services include:

- Assistance with installation and start-up

- Training on product operation and maintenance

- Troubleshooting and diagnosis of product issues

- Repair and replacement of faulty components

- Upgrades and retrofits to improve product performance

- Technical documentation and manuals

- 24/7 customer support and emergency services

Packing and Shipping:

Product Packaging:

- The Control Valve Positioner will be securely packaged in a cardboard box to prevent any damage during shipping.

- The product will be wrapped in bubble wrap or foam to provide additional protection.

- All necessary installation instructions and product manuals will be included inside the box.

Shipping:

- Orders will be processed within 24-48 hours of receiving payment.

- Standard shipping via UPS, FedEx, or USPS will be used.

- Customers will receive a tracking number once the product has been shipped.

- Shipping times may vary depending on the customer's location.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews