Product Description:

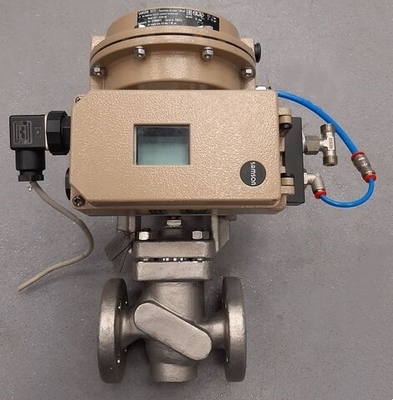

The Type 3730 electro-pneumatic positioner series is a reliable and versatile solution designed to meet the demands of a wide range of industrial applications. This positioner series offers a variety of different models to ensure compatibility with any process requirements and user needs. Two of the most basic control positioners in the range are the 3730-0 and 3730-1.

The 3730-2 positioner model features full function parameterization and advanced diagnostics, which take the capabilities of this series to the next level. In addition, SAMSON introduces communication protocols such as HART (3730-3), Profibus (3730-4), and Foundation Fieldbus (3730-5) beyond the 3730-2. Full function parameterization includes the option to characterize the reference variable, travel range, characteristic (e.g. linear and equal percentage), and performance characteristics (e.g. PID control coefficients). Advanced diagnostics complement this feature by offering enhanced functions such as status message logging, data logging, histograms (travel setpoint deviation, and cycle counter), drive signals (steady and hysteresis), end position trending, static characteristic testing, partial stroke testing, and full stroke testing.

Features:

The Electropneumatic positioner with HART® communication is a versatile device designed for attachment to linear actuators according to IEC 60534-6, VDI/VDE 3847, or SAMSON integral attachment. It is also compatible with rotary actuators according to VDI/VDE 3845 and double-acting actuators with Type 3710 Reversing Amplifier.

This high-performance positioner features simple one-knob, menu-driven operation, and can be configured with a computer over the SSP interface using the TROVIS-VIEW software. It boasts a configurable automatic start-up function, thanks to four different initialization modes, and also has integrated EXPERTplus diagnostics for control valves.

The SAM DIGITAL READY positioner comes with a calibrated travel sensor without gears that are susceptible to wear, and a sub (substitution) initialization mode that allows the device to be started up in case of emergency whilst the plant is running without having to change the valve position. All parameters are saved in non-volatile EEPROM, and the device also has a two-wire system with small electrical load of 410 Ω.

Other features of this device include an adjustable output pressure limitation, an adjustable tight-closing function, automatic zero monitoring, an integrated temperature sensor and operating hours counter, and two standard programmable position alarms. It also offers self-diagnostics and messages as condensed state conforming to NAMUR Recommendation NE 107, issued over a fault alarm contact or optional analog position transmitter. Moreover, it comes with a DTM file available for integration into FDT frame applications according to specification 1.2.

The Electropneumatic positioner with HART® communication is housed in either a die-cast aluminum or stainless steel housing, and it can be attached to a variety of actuators. The positioner is designed for any desired mounting position but not suspended mounting.

This positioner features an easy-to-read display that can be viewed from any mounting position thanks to rotatable reading direction. It has preset parameters, and only values deviating from the standard need to be adjusted. This feature makes it easy to use and reduces the time required for configuration.

The Electropneumatic positioner with HART® communication also has an integrated EXPERTplus diagnostics system for control valves, thus providing users with real-time information on the status of their valves. This is all made possible by the positioner's innovative one-knob, menu-driven operation system, which allows for easy and quick configuration of the device.

The Electropneumatic positioner with HART® communication is an advanced positioner that comes with an array of features that make it easy to use and versatile. Its compact design and die-cast aluminum or stainless steel housing make it suitable for use in a wide variety of applications, and its ability to be attached to a variety of actuators makes it a versatile solution for all types of control valve applications.

This positioner is ideal for any industrial environment and is designed to work with many different types of control valves. It is easy to install and configure, thanks to its simple one-knob, menu-driven operation system, and can be configured with a computer over the SSP interface using the TROVIS-VIEW software.

The Electropneumatic positioner with HART® communication comes with a number of other advanced features, including integrated EXPERTplus diagnostics for control valves, a sub (substitution) initialization mode, and automatic zero monitoring. It also has self-diagnostics and messages as condensed state conforming to NAMUR Recommendation NE 107, issued over a fault alarm contact or optional analog position transmitter.

Technical Parameters:

| Brand Name: |

Samson |

| Model Number: |

3730-3 Samson Valve Positioner |

| Media: |

Gas |

| Signal range: |

4 To 20 MA |

| Static destruction limit: |

100 MA |

| Deviation: |

≤1 % |

| Sensitivity: |

≤0.1 % |

| Temperature: |

≤0.15 %/10 K |

| Hysteresis: |

≤0.3 % |

| Direction of action: |

Reversible |

This table shows the technical parameters for the Valve Position Regulator. This product is manufactured by Samson and is also known as the Smart Valve Positioner. It is designed for use with gas media and has a signal range of 4 To 20 MA. The model number for this product is 3730-3. Other technical parameters include a static destruction limit of 100 MA, a deviation of ≤1 %, sensitivity of ≤0.1 %, temperature of ≤0.15 %/10 K, hysteresis of ≤0.3 %, and reversible direction of action.

Applications:

The Samson 3730-3 Electropneumatic Valve Positioner is a highly trusted and utilized tool within industrial settings due to its advanced control capabilities and its reliable performance. As one of the leading valve positioners available it has numerous applications across many industries including:

- Chemical Processing: The Samson 3730-3 provides precise control of fluid flow, pressure, and temperature, optimizing chemical reactions and improving overall safety.

- Oil and Gas: The valve positioner is used to regulate valves in pipelines and refineries, ensuring consistent flow and pressure for seamless and efficient operation.

- Power Generation: Samson 3730-3 controls valves in turbines and boilers, guaranteeing stable power production and reducing any downtime.

- Water Treatment: The valve positioner manages inflow and outflow valves, helping to accurately dose and maintain water quality.

- Pharmaceuticals: The tool provides precise valve control in sterile environments, ensuring product quality and complying with stringent regulations.

The Samson 3730-3 Valve Positioner is also capable of integrating seamlessly with many control systems via digital communication, making it easy to remotely monitor and diagnose any potential issues. Its robust construction and high precision make it the ideal choice for even the harshest industrial environments, ultimately contributing to enhanced process efficiency and increased reliability.

Support and Services:

Our Control Valve Positioner product is designed to offer precise control of valve positioning for optimal performance in industrial processes. We provide comprehensive technical support and services to ensure that our customers can maximize the benefits of this product. Our technical support team is available to provide assistance with installation, configuration, and troubleshooting. In addition, we offer training services to help our customers understand how to use the Control Valve Positioner effectively. Our services also include maintenance and repair to ensure that the product is operating at peak performance. Contact us for more information about our technical support and services for the Control Valve Positioner.

Packing and Shipping:

Product Packaging:

- The control valve positioner will be securely packaged in a sturdy cardboard box.

- The box will be lined with bubble wrap to provide additional protection during shipping.

- All necessary documentation, including manuals and installation instructions, will be included in the package.

Shipping Information:

- The control valve positioner will be shipped via a reputable courier service.

- Shipping fees will be calculated based on the destination and weight of the package.

- The estimated delivery time will be provided to the customer upon checkout.

- The customer will be provided with a tracking number to monitor the status of their shipment.

- Any issues or concerns regarding shipping can be directed to our customer service team.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews