Product Description:

Stock of Valve Positioners and Accessories

Chinese control valve manufacturers offer a variety of valve positioners and accessories to choose from. Below are some of the products commonly available in stock:

Fisher

- DVC6200

- DVC2000

- 3582I

- 3620J

- 3720

- 3661 valve positioners

- 2625

- VBL pneumatic amplifiers

- 4211 and 4210 position transmitters

- 67CFR and 67CFSR filter pressure reducing valves

- DLC3100 and DLC3010 float level gauges

Masoneilan

- SVI3-21111112 single acting without feedback

- SVI3-21111212 single acting with feedback

- SVI3-21121212 single acting with display and feedback

- SVI1000/G/IM/PR single acting waiting for feedback with magnetic pole

- SVI2-21123111 single acting without feedback

- SVI2-22123121 double acting with feedback and display

- SVI2-21123121 single acting with feedback and display valve positioner

- BR200 and BR400 pneumatic amplifier

- 78-40 filter pressure reducing valve

Samson

- 3730-31001

- 3730-31000

- 3725

- 4763 valve positioners

Flowserve

- 520MD and 3200MD-28-D6-E-04-40-0G-00 double acting/single acting without feedback

- 3200MD-28-D6-E-04-40-0G-0F double acting/single acting with feedback

- 3800MD valve positioner

Azbil

- AVP100, AVP102, AVP200, AVP201, AVP202, AVP300, AVP301, AVP302, AVP307 valve positioners

Neles

- ND7000

- ND9103HX8T

- ND9106HX8T

- ND9203HE8T

- ND9206HE8T valve positioners

ABB

- V18345-1010121001

- V18345-1010221001

- V18345-1010521001 valve positioners

- EDP300 valve positioner

Siemens

Rotork

Foxboro

- SRD991

- SRD998

- SRD960 valve positioners

Other Brands

- ASCO, Norgen, Burkert Solenoid valves, conventional models in stock

Features:

Main features of valve positioners

Valve positioners are used to control and adjust pneumatic control valves. The main features of valve positioners include:

- High-precision adjustment: Intelligent valve positioners are capable of providing high-precision adjustment through microprocessing technology. This ensures a perfect balance between signal and feedback.

- Fast response: Intelligent positioners have the characteristics of fast response and can perform actions quickly.

- Automatic setting: Intelligent positioners have the function of automatic setting which simplifies the debugging process.

- High sensitivity: Pneumatic valve positioners are very sensitive to changes in working conditions and can adjust and work stably in time.

- Simple structure: The structure of pneumatic valve positioners is relatively simple and easy to maintain and repair.

- Strong adaptability: Pneumatic valve positioners do not have high requirements for pneumatic control valves and are suitable for various pressure ranges.

- Split-range control: Pneumatic valve positioners can be split-range controlled, and one control signal can control multiple positioners.

Working principle of valve positioner

Valve positioners are an essential component for controlling pneumatic control valves. The working principle of valve positioners is based on the conversion of electrical signals into pressure signals. This pressure is used to control the position of the valve stem, which adjusts the flow rate of the fluid.

The core mechanism of valve positioners includes the nozzle flapper and the film chamber. These components sense the pressure and adjust the position of the valve stem, which achieves the purpose of precise control.

Technical Parameters:

| Technical Parameter |

Value |

| Minimum Current |

3.6 MA for Display, 3.8 MA for Operation |

| Customized Support |

OEM |

| Feature |

Neles Control Valve Neles Positioner |

| Sensitivity |

≤0.1 % |

| Degree of Protection |

IP 66/NEMA 4X |

| Warranty |

1 Year |

| Media |

Gas |

| Place of Origin |

Chinese |

| Temperature of Media |

High Temperature, Low Temperature, Medium Temperature, Normal Temperature |

| Deviation |

≤1 % |

Applications:

The petrochemical industry utilizes valve positioners to regulate parameters such as flow and pressure. Valve positioners play a particularly important role in the production process of liquefied gas and ethylene and are capable of satisfying various stages in the production process.

In sewage treatment, valve positioners are utilized to control the flow of sewage and clean water and ensure that equipment operates smoothly while maintaining water quality.

The thermal power generation and nuclear power industries widely use valve positioners to control fluid pipelines, improve equipment reliability and safety, and ensure power station operation stability.

The tap water industry relies on valve positioners for water pipe and valve inspections, water level and pressure control, and real-time monitoring through external signals.

In the metallurgical industry, intelligent valve positioners accurately control valves in smelting furnaces and heat treatment furnaces, ensuring the efficiency and safety of the smelting process.

In the pharmaceutical industry, valve positioners are essential for adjusting the flow and direction of liquid medications and solvents, providing precise guarantees for drug production.

The environmental protection field employs intelligent valve positioners to strictly regulate valves in wastewater and waste gas treatment equipment, facilitating the normal operation of environmental protection facilities and compliance with emission standards.

Support and Services:

Our Pneumatic Control Valves are designed to provide accurate control of various fluid media such as air, water, and oil. They are suitable for use in a wide range of applications, including process control, HVAC, and industrial automation.

Our technical support team is available to assist with any technical questions or issues that may arise during installation, operation, or maintenance of our Pneumatic Control Valves. We also offer a range of services, including calibration and repair, to ensure that our products continue to perform optimally over their lifespan.

Packing and Shipping:

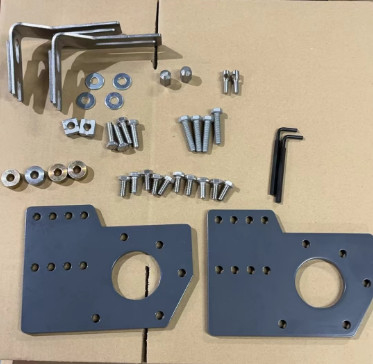

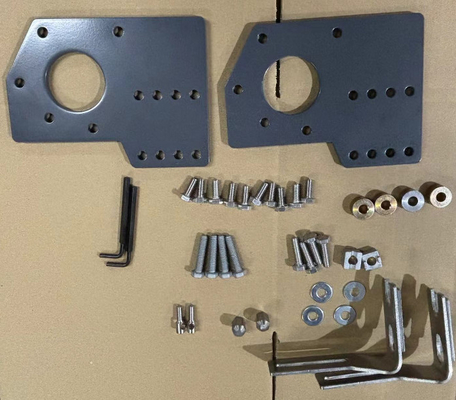

Product Packaging:

- The pneumatic control valve will be packed in a sturdy cardboard box to prevent any damage during transportation.

- The box will be labeled with the product name, quantity, and any other necessary information.

- Inside the box, the product will be wrapped in bubble wrap to provide extra protection.

Shipping:

- The product will be shipped via a reliable courier service.

- The shipping cost will be calculated based on the weight and dimensions of the package.

- The estimated delivery time will be provided to the customer and can vary depending on the destination.

- The customer will receive a tracking number once the product has been shipped.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews