A Comprehensive Overview of the Rosemount 2051HT Pressure Transmitter

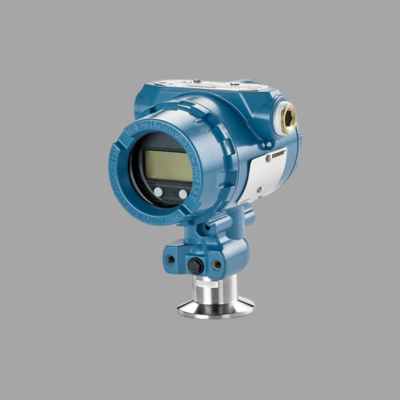

The Rosemount 2051HT is a high-performance, differential pressure (DP) transmitter engineered by Emerson Electric Co. under its renowned Rosemount measurement brand. It is specifically designed for demanding, high-temperature applications across a wide spectrum of heavy industrial processes. As a stalwart in the 2051 series, the HT variant builds upon a legacy of reliability and accuracy, incorporating specialized design features to handle environments that would be prohibitive for standard transmitters.

The core of the 2051HT's functionality lies in its advanced sensor technology, which is based on a proven capacitive ceramic sensor, specifically alumina ceramic. Unlike traditional oil-filled sensors that can degrade under extreme heat, the 2051HT's sensor is a dry, all-welded system. This fundamental design choice eliminates the risk of sensor fill fluid degradation or leakage, which is a critical point of failure in high-temperature scenarios. The capacitive principle involves a diaphragm that deflects minutely under applied pressure, changing the capacitance between itself and a fixed electrode. This change is precisely measured and converted into a highly accurate digital signal.

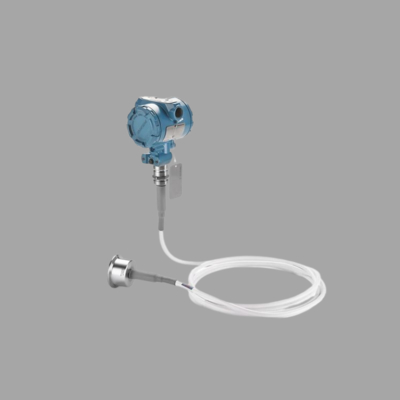

The defining characteristic of the 2051HT is its exceptional ability to handle extreme process temperatures. It is capable of directly measuring process media with temperatures up to 375°C (707°F) without requiring external cooling apparatus like impulse piping, siphon seals, or capillary tubes. This capability is a game-changer in applications such as furnace draft measurement, boiler combustion control, and catalyst pressure drop monitoring in reformers, where hot process gases are the norm. By eliminating the need for complex and maintenance-intensive external cooling systems, the 2051HT dramatically reduces installation costs, minimizes potential leak points, and improves overall system reliability and safety.

The transmitter is housed in a robust, cast aluminum enclosure that provides excellent protection against harsh environmental conditions, rated at NEMA 4X (IP66). This makes it suitable for installation outdoors or in wet, dusty areas. It features a large, backlit liquid crystal display (LCD) that can be configured to show pressure readings in various engineering units, percentage of range, or a custom text message. The local user interface (LUI) is intuitive, allowing for easy configuration, calibration, and diagnostics without the need for external handheld communicators, though it remains fully compatible with Emerson's AMS Device Manager and the universal HART communicator.

Communication is facilitated via the industry-standard HART protocol (Highway Addressable Remote Transducer). This 4-20 mA analog signal with superimposed digital communication allows for robust, bidirectional data exchange. Users can remotely read process variables, perform diagnostics, and reconfigure parameters from the control room, enabling predictive maintenance and reducing the need for trips into potentially hazardous areas.

In terms of performance, the 2051HT offers high accuracy, typically up to ±0.075% of calibrated span, ensuring precise measurement for critical control and optimization loops. Its stability is a key benefit, reducing measurement drift over time and minimizing the need for frequent recalibration.

| Category |

Details |

| Product Name |

Emerson Rosemount 2051HT High-Temperature Differential Pressure Transmitter |

| Series |

Part of the Rosemount 2051 Series (HT = High Temperature version) |

| Core Sensor Technology |

Dry, all-welded capacitive ceramic sensor (alumina ceramic)Eliminates failure risks of oil-filled sensors under extreme heat |

| Measurement Principle |

Pressure deflects diaphragm → capacitance changes → converted to a precise digital signal |

| High-Temperature Capability |

Direct measurement of process media up to 375°C (707°F)No impulse piping, siphon seals, or capillaries required |

| Main Advantages |

- Eliminates cooling accessories → lower installation cost- Fewer leak paths → enhanced safety- Higher system reliability and reduced maintenance |

| Typical Applications |

- Furnace/boiler draft measurement- Hot gas/liquid filter and strainer monitoring- Catalyst bed pressure drop in reformer units- Flow and level measurement of hot oils, molten salts, and heat-transfer fluids |

| Performance |

- Accuracy: ±0.075% of span (typical)- Excellent long-term stability with reduced recalibration needs |

| Construction |

- Housing: Cast aluminum- Protection rating: NEMA 4X / IP66- Suitable for outdoor, dusty, or wet conditions |

| Display & Operation |

- Large backlit LCD display- Shows pressure, % of span, or custom text- Intuitive Local User Interface (LUI) for configuration and diagnostics |

| Communication |

- 4–20 mA analog output with HART digital protocol- Remote configuration, diagnostics, and predictive maintenance- Compatible with AMS Device Manager and universal HART communicator |

| Target Industries |

Power, Oil & Gas, Refining, Chemical, and other high-temperature process industries |

Key applications include:

-

Furnace and Boiler Draft Measurement: Directly measuring very low differential pressures in high-temperature flue gas streams.

-

Filter and Strainer Monitoring: Detecting clogging in inlet air filters or liquid strainers exposed to hot media.

-

Catalytic Reformer Units: Monitoring pressure drop across catalyst beds, which is crucial for process efficiency and safety.

-

High-Temperature Fluid Processes: Measuring flow and level of hot oils, molten salts, and other heat transfer fluids.

In summary, the Rosemount 2051HT is a specialized, robust, and highly reliable differential pressure transmitter. Its primary advantage is its integral temperature management, allowing for direct installation on high-temperature processes. This design significantly lowers lifecycle costs, enhances safety by reducing leak paths, and delivers the exceptional measurement performance and durability that the Rosemount brand is known for, making it an ideal solution for the most challenging conditions in the power, oil and gas, refining, and chemical industries.

Please contact Sean at 13032169980

Company website: https://shanghaixiangjing.gys.cn/company-information.html

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews