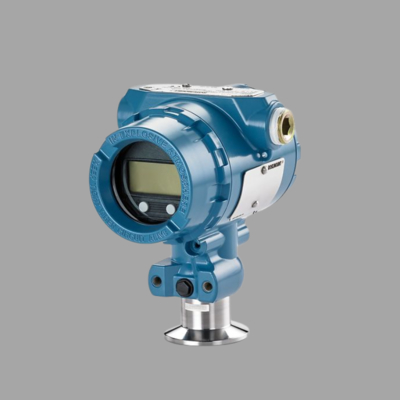

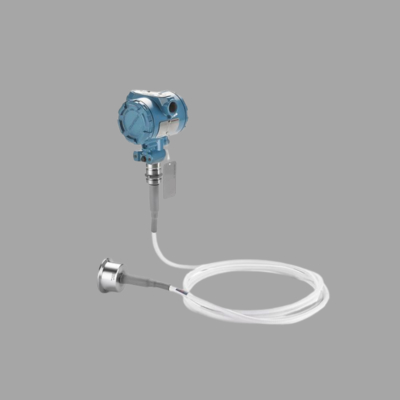

Rosemount 3051HT High Temperature Pressure Transmitter: A Comprehensive Overview

The Rosemount 3051HT is a specialized, high-performance pressure transmitter engineered by Emerson to deliver exceptional reliability and accuracy in the most demanding high-temperature process applications. As a distinguished member of the renowned 3051 series, the "HT" designation signifies its unique capability to directly mount on processes where the media temperature can reach extremely elevated levels that would damage or degrade a standard transmitter. It is specifically designed to measure gauge pressure, absolute pressure, and liquid level in services involving superheated steam, molten metals, high-temperature hydrocarbons, and other challenging fluids, making it an indispensable tool in industries like power generation, oil and gas, and chemical processing.

Core Innovation: Direct Mounting on High-Temperature Processes

The primary differentiator of the 3051HT is its ability to withstand immense heat. While a standard pressure transmitter requires a cooling element (like a siphon or capillary) to protect its sensitive electronics from hot media, the 3051HT is designed for direct flange mounting. This is achieved through a sophisticated and robust internal design. The heart of this system is the sensor module, which is isolated from the process heat by an integral, proprietary heat sink and a filled capillary system. This system acts as a thermal barrier, effectively dissipating heat and ensuring that the sensor's oil-filled isolation diaphragms remain within their safe operating temperature range. This direct-mount capability eliminates the potential failure points and maintenance issues associated with external cooling assemblies, leading to enhanced measurement integrity and reduced lifecycle costs.

Unmatched Performance and Robust Construction

The 3051HT is built for performance in harsh conditions. It boasts reference accuracy as high as ±0.075% of span, providing the precision necessary for critical control and efficiency calculations, such as monitoring steam turbine performance. Its exceptional long-term stability, a hallmark of the Rosemount 3051 series, minimizes measurement drift over time, ensuring consistent performance and reducing the need for frequent recalibration.

The transmitter's construction is inherently rugged. The sensor flange and process connections are typically manufactured from durable 316 stainless steel or higher alloys to resist corrosion. The electronics are housed in a weatherproof, cast aluminum enclosure rated NEMA 4X / IP66, protecting them from environmental hazards like moisture, dust, and electromagnetic interference (EMI/RFI). This robust build ensures reliable operation in outdoor or challenging plant environments.

Advanced Diagnostics and Intelligent Features

Leveraging the power of the HART® (Highway Addressable Remote Transducer) and FOUNDATION™ Fieldbus protocols, the 3051HT is more than just a measurement device; it is an intelligent asset. It features a comprehensive suite of embedded diagnostics that continuously monitor the health of the transmitter and the process. These diagnostics can alert operators to potential issues such as sensor drift, electronics failure, or process anomalies like plugged impulse lines. This proactive approach to maintenance enables predictive strategies, helping to prevent unplanned shutdowns and improving overall plant safety and availability. Configuration is simplified through the intuitive local operator interface (LOI) with a plain-English display or via any HART communicator or asset management software like Emerson's AMS Device Manager.

| Category | Details |

|---|

| Product Positioning | Specialized high-temperature pressure transmitter in Emerson’s Rosemount 3051 series. Designed for direct mounting on extreme heat processes without external cooling elements. Measures gauge pressure, absolute pressure, and liquid level in harsh high-temperature services. |

| Core Innovation | - Direct flange mounting on high-temperature processes.- Integral proprietary heat sink + filled capillary system isolates sensor from process heat.- Acts as a thermal barrier, keeping diaphragms within safe limits.- Eliminates need for siphons or capillaries, reducing failure points and maintenance. |

| Performance | - Reference accuracy: ±0.075% of span.- Exceptional long-term stability reduces drift and recalibration needs.- Suitable for critical control (e.g., steam turbine monitoring, efficiency calculations). |

| Construction & Materials | - Rugged build with 316 stainless steel or higher alloy process connections.- Electronics in cast aluminum housing, NEMA 4X / IP66 rated.- Resistant to moisture, dust, and EMI/RFI.- Reliable in outdoor and demanding plant conditions. |

| Diagnostics & Smart Features | - Supports HART® and FOUNDATION™ Fieldbus communication protocols.- Embedded diagnostics monitor transmitter and process health.- Alerts for sensor drift, electronics failure, plugged impulse lines, etc.- Enables predictive maintenance to prevent unplanned shutdowns.- Configuration via Local Operator Interface (LOI), HART communicator, or AMS Device Manager. |

| Applications & Industries | - Power Generation: Superheated/main steam lines, turbine inlet/outlet, feedwater pump recirculation.- Oil & Gas: Furnace headers, coker units, catalytic cracking units.- Chemical & Petrochemical: High-temperature reactors, distillation columns, heat transfer systems.- Pulp & Paper: Recovery boilers, black liquor systems. |

| Overall Advantages | - Direct-mount design eliminates cooling accessories.- Delivers superior accuracy and stable measurement in extreme heat.- Rugged construction ensures durability.- Advanced diagnostics support predictive maintenance.- Enhances efficiency, safety, and uptime in high-temperature industrial environments. |

Typical Applications and Industries

- Power Generation: Direct measurement of superheated and main steam lines, turbine inlet/outlet, and feedwater pump recirculation.

- Oil & Gas: Monitoring critical processes in refineries, such as refinery furnace headers, coker units, and catalytic cracking units.

- Chemical & Petrochemical: Handling high-temperature reactors, distillation columns, and heat transfer systems.

- Pulp & Paper: Applications around recovery boilers and black liquor systems.

In summary, the Rosemount 3051HT is a premier solution for high-temperature pressure measurement. Its innovative direct-mount design eliminates the need for error-prone cooling accessories, delivering superior accuracy, exceptional reliability, and advanced diagnostics. By ensuring precise and stable measurement in the most thermally hostile environments, the 3051HT plays a vital role in optimizing process efficiency, enhancing safety, and maximizing operational uptime in the world's most demanding industrial facilities.

Please contact Sean at 13032169980

Company website: https://shanghaixiangjing.gys.cn/company-information.html

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews